Juming Conveyor offers a comprehensive range of conveyor rollers suitable for a wide variety of conveyor systems. We have a diverse selection of roller tubes, including aluminum, plain steel, galvanized steel, stainless steel, and PVC, to meet your specific material handling requirements. These rollers can be seamlessly integrated into your conveyor systems.

We take pride in our ability to provide customized conveyor rollers tailored to your unique conveyor equipment. Our gravity roller conveyors are designed to streamline the movement of products and materials, making tasks such as warehousing, package handling, manufacturing, and distribution more efficient.

For those in need of custom roller configurations, we offer roller brackets that can be easily installed for single or multiple rollers. Additionally, we supply conveyor parts to complement our roller conveyor systems.

| 1.HDPE Roller | 2.UHMWPE ROLLER | 3.Garland roller |

|

HDPE rollers offer excellent wear and corrosion resistance, ideal for abrasive materials like sand, iron ore, and coal. They are lightweight and cost-effective. |

UHMWPE rollers, known as the "amazing plastic," provide exceptional wear resistance, corrosion resistance, and self-lubrication. They excel in various applications. |

Garland rollers form continuous chains, supporting conveyor belts in mining and material handling. Available in 3-roller or 5-roller configurations.

|

| Contact us | Contact us | Contact us |

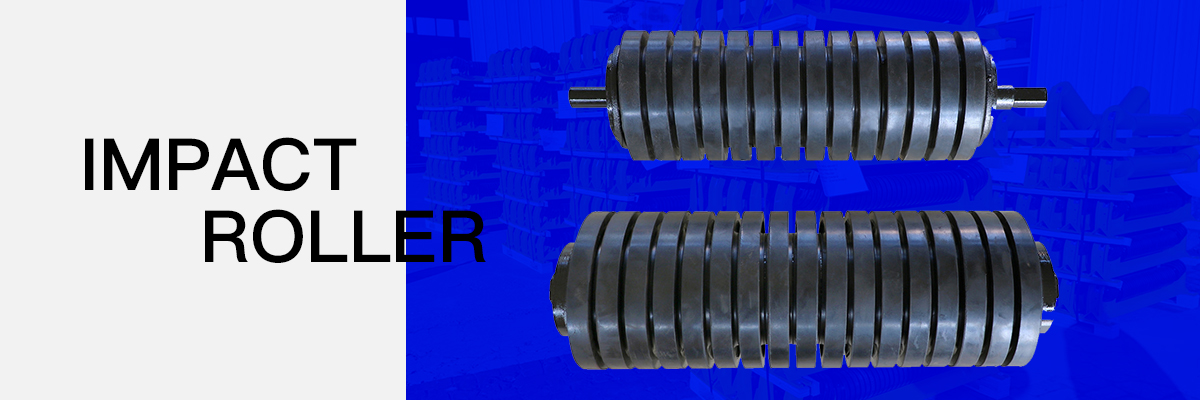

4.Impact roller

Impact rollers are designed to protect conveyor belts from damage caused by material falling from a height. They extend the conveyor belt's service life and are made of high-quality rubber for durability.

5.Guide roller

The guide roller material is waterproof and dustproof of steel.Guide rollers can be used to guide or point an object in a particular direction. As far as a boat trailer is concerned, the guide roller is what the boat comes in contact with first when loading. When applied in the context of a rolling conveyor application, the guide roller helps maintain a belt conveyor’s alignment and integrity while it is in motion.Effectively prevent the belt from running off.The return roller for conveying the whole material is installed below to support the conveyor belt.

| 6.Return roller | 7.Troughing roller |

|

Conveyor Return Roller are installed on the side under the conveyor to provide support to the returning conveyor belt. these conveyor return rollers are designed to enable use as carry idler and support the conveyor belt from below in a flat belt situation.The return roller is the same as the carrying roller, but the carrying roller is used below. |

Carrying rollers are utilized to provide support to the conveyor belt and are fitted on the notch frame, transition idler frames and Groove shape forward slanted idler frame. Quality bearing are used for the rollers, multi-labyrinth sealing, properly lubricated and sealed to enhanced performance and critical specification.The carrying roller is made of steel pipe and is dustproof and waterproof. |

| Contact us | Contact us |

| 8.Garland roller set | 9. Carrier Roller Set |

| Garland Roller Sets are used to handle heavy, bulky materials in belt conveyors. They ensure reliable support and guidance. |

Carrier Roller Sets support and guide conveyor belts, ensuring efficient material handling in various applications. |

| Contact us | Contact us |

| 10.Comb roller | 11.Spiral roller | 12.Friction roller |

|

Comb rollers convey and clean viscous materials, preventing belt misalignment and material buildup. They are a reliable solution to common belt conveyor issues. |

Spiral rollers self-clean, reducing material buildup on conveyor belts. They automatically correct belt alignment, extending belt life. |

Friction rollers are vital components of conveyor idler sets, correcting belt deviations and maximizing belt protection. |

| Contact us | Contact us | Contact us |

| 13.Wing roller | 14.Tapered roller |

| Wing rollers help maintain belt alignment in Variable Angle Troughing Sets, suitable for mobile crusher and screening equipment. |

Tapered rollers correct belt deviations and extend belt life, commonly found at both ends of idler sets. |

| Contact us | Contact us |

| 15.Self Aligning return roller set | 16.Self aligning carrier roller set |

|

These rollers correct belt tracking, preventing belt injury, material spillage, and downtime.

|

Self-aligning carrier roller sets ensure stable conveyor belt movement by automatically correcting belt deviations. |

| Contact us | Contact us |

| 17.Off-set roller set | 18.Self aligning V-return roller set |

| Offset carrying roller sets reduce belt snag risk and damage with their reduced height and roller gap. Commonly used in underground mines. |

V-return roller sets positively track the belt on the return side, increasing tracking force and featuring sealed-for-life ball bearings. |

| Contact us | Contact us |

19.Impact roller set

Impact roller sets protect conveyor belts from damage by absorbing impacts. They come in various angles to suit your needs.

1. Excellent product quality

We are committed to providing superior product quality and our products like HDPE Roller and UHMWPE ROLLER perform exceptionally well in a variety of applications. We use the highest standards of materials and manufacturing processes to ensure each product has exceptional wear resistance, corrosion resistance and reliability.

2. Customer satisfaction

Customer satisfaction has always been our top priority. Not only do we provide excellent products, we also provide excellent customer service. Our team of professionals is ready to answer your questions, provide support, and ensure you are satisfied with our products and services.

3. Customized solutions

No matter how unique your needs are, we can provide you with a customized solution. We understand that each customer's needs are different, so we are willing to work with you to tailor a product to meet your specific requirements.

4. Industry experience

We have extensive industry experience and have been catering to the needs of various industries for many years. This enables us to better understand the challenges of different industries and provide the best solutions to our customers.

5. Reliability and trust

Our reliability is the basis of our success. Customers trust our products and rely on us to provide superior solutions. We strive to maintain this trust and ensure that our products and services are always of high quality.

At our company, we not only provide great products, but also great experiences. By choosing us, you'll work with a trustworthy partner to provide you with the best possible support for your project.

If you have any needs, please contact us immediately. We will reply to you as soon as possible